Three Phase Transformer Manufacturers

buy 3 phase variable voltage transformer, three phase isolation transformer.7.5 kva 3 phase transformer, three phase core type transformer, view 3 phase variac transformer price

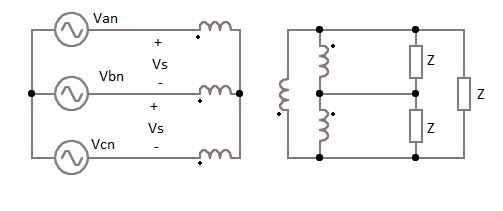

3 phase to single phase transformers produce single phase electricity as output from a three phase electricity as input. Depending on the mains supply lines, three phase electricity will be needed to be converted in single phase before supplying to other single phase transformer. The electricity will then be stepped down and supplied to domestic units and other required operands.

Three Phase Transformer Manufacturers

7.5 kva 3 phase transformer

3 phase variable voltage transformer

view 3 phase to 1 phase transformer, 10kva 3 phase transformer, three phase auto transformer, 3 phase isolation transformer cost, 3 phase to single phase transformer for sale At lowest Price In India and africa

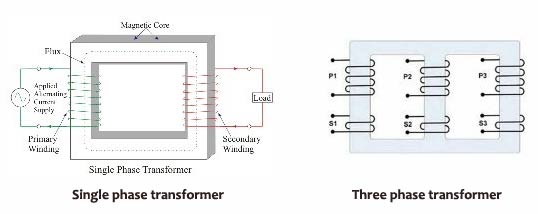

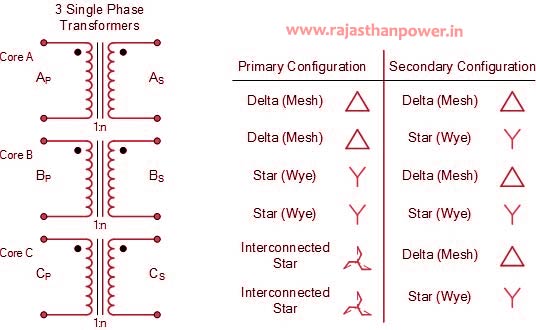

A 3 Phase to 1 Phase Transformer has three sets of coil windings at the core. It almost looks like a combination of three single phase transformers from the inside. The windings are put up onto a single core and the output will be a single phase. This is the direct opposite function of single phase to Three Phase converter transformer. The Three Phase Core Type Transformer can be connected to the network in different configurations like delta and mesh. A transformer 3 phase to single Phase can be configured with the network according to the requirements of the application.

Types and operations

The sizes, prices, operations and quality differ from the requirement of the end user. There is small 3 phase transformer and large transformer, copper and aluminium windings, low and high voltage ones and much other differentiations available in the market. A Three Phase Auto Transformer would act as an automated voltage regulator. Larger ones without a connection between the coil and the outside tank are called to have a buried delta winding.A 3 Phase Variable Voltage Transformer or 3 Phase Variac Transformer produces a variable AC as output. Sensitive electric circuits with sensitive electronic devices can apply this kind of transformer to get a distortion free output.

These come in different capacities such as 10kva 3 Phase Transformer, 5kva transformer 3 phase, step up transformer 220v to 380v 3 phase, 7.5 Kva 3 Phase Transformer and in other specifications as required. Three Phase Transformer Manufacturers like [company name] can fulfill all your requirements.Three phase isolation transformer isolates the apparatus from source. The isolation is needed for safety reasons. The transformer acts in a way that even power surges that occur in the supply grid do not reach the equipment. The 3 Phase Isolation Transformer comes in copper wound and aluminium wound models. The copper ones are more expensive due to the cost of the metal. In comparison both have similar operational quality and capacity and the aluminium ones are foreseeable in the future transformers.

A 3 phase control transformer is a member of control transformers. Control transformers accommodate high quality insulations. The primary and secondary windings, layer to layer windings and turn to turn windings are insulated at different levels. They are also resistant to moisture because of the vacuum impregnation and resin used in the making.

A three phase transformer may be a three-legged iron core. Each leg incorporates a individual essential and auxiliary winding. Most power is scattered within the shape of three-phase AC. Fundamentally the power company generators create power by turning 3 coils or windings through a attractive field inside the generator. Three-phase could be a common strategy of electric control transmission. It could be a type of framework utilized to control engines and numerous other gadgets. Three phase frameworks may or may not have a impartial wire. A impartial wire permits the three phase framework to utilize a better voltage whereas still supporting lower voltage single phase appliances.Three-phase Transformers are the spine of electrical power dispersion whether Delta or Star connected windings

| three phase transformer | single phase transformer |

| three phase transformer contains six coils, three for primary side, and another three coils for the secondary side | Single phase transformer contains two coils, one on the primary side, and another one on the secondary side |

| three phase transformer has twelve terminals with different connection for them for star or delta connections. | Single phase transformer has four terminals, two on the input (phase & neutral), and two on the output (phase & neutral), no delta or star connections are available here |

| three phase transformers are most used as a power or distribution transformers, with high rated KVA. | Single phase transformers are most used in the household devices applications, such as TV, Microwave Oven, Phone Charger, etc |

| three phase transformers have many cooling systems depending on the transformer rated power, may be by forced oil, oil, air, forced air or by forced water. | In most cases, no cooling system is required for single phase transformer |

| Power rating |

1 ÷ 100 kVA |

| Input voltage | 3 x 400 V Three phase |

| Output voltage |

230 V Single phase |

| Frequency | 50/60 Hz |

| Ambient temp. |

40 ºC (series TTMS) 30º C (series TTMC) |

| Connection group |

V – V inverted |

| Insulation class |

F (155 ºC) |

| Protection degree |

IP-00 (series TTMS) IP-23 (series TTMC) |

| Safety class |

Class I |

| Test voltage |

4 kV |

| Marked | CE |

| Standard | IEC/UNE-EN 61558-1 IEC/UNE-EN 60076-11 |

| Three Phase Transformer Manufacturers Export to | India, Africa, Kenya, Malawi, Nigeria, Tanzania, Uganda, Rwanda, Bangladesh, Nepal, Malaysia |

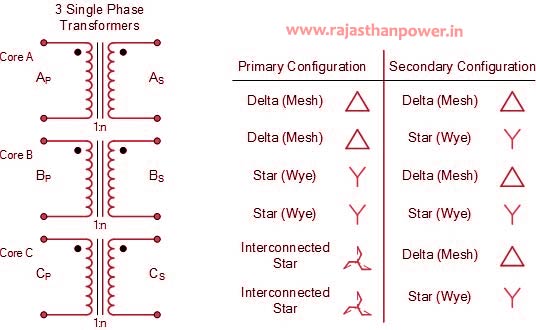

A transformer for utilize with 3-phase power is developed by winding three single phase transformers on a single core.

The three phase transformer comprises three transformers either isolated or combined with one core.There are four conceivable connections for a 3-phase transformer bank.

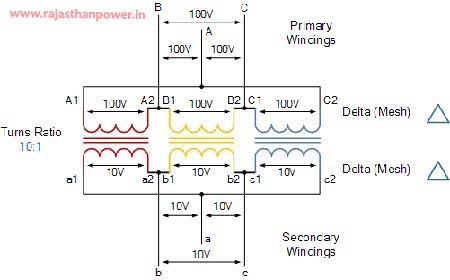

- Δ – Δ (Delta – Delta) Connection

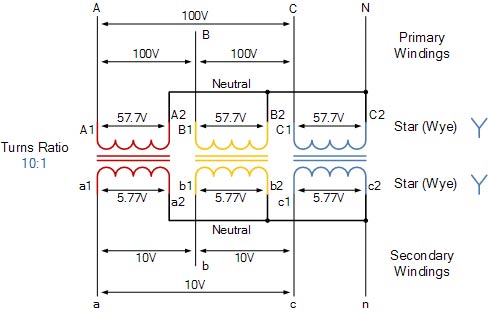

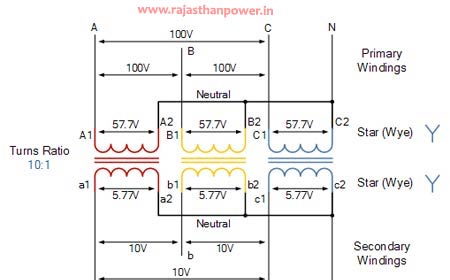

- Υ – Υ (Star – Star) Connection

- Δ – Υ (Delta – Star) Connection

- Υ – Δ (Star – Delta ) Connection

Transformer Winding Identification

| Connection | Primary Winding | Secondary Winding |

| Delta | D | d |

| Star | Y | y |

| Interconnected | Z | z |

Delta-Delta (Δ-Δ) Connection :

- This connection is generally used for large, low-voltage transformers. Number of required phase/turns is relatively greater than that for star-star connection.

- The ratio of line voltages on the primary and the secondary side is equal to the transformation ratio of the transformers.

- This connection can be used even for unbalanced loading.

Υ – Υ (Star – Star) Connection

- Star-star connection is generally used for small, high-voltage transformers. Because of star connection, number of required turns/phase is reduced (as phase voltage in star connection is 1/√3 times of line voltage only). Thus, the amount of insulation required is also reduced.

- The ratio of line voltages on the primary side and the secondary side is equal to the transformation ratio of the transformers.

- Line voltages on both sides are in phase with each other.

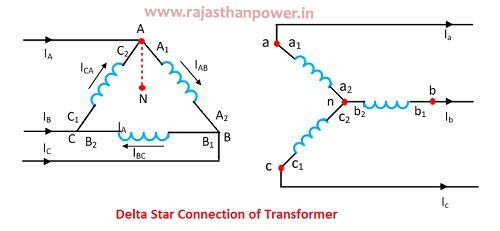

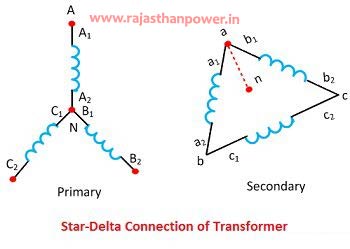

Δ – Υ (Delta – Star) Connection(OR Delta-Wye (Δ-Y))

- The primary winding is connected in delta and the secondary winding is connected in star with neutral grounded. Thus it can be used to provide 3-phase 4-wire service.

- This type of connection is mainly used in step-up transformer at the beginning of transmission line.

- The ratio of secodary to primary line voltage is √3 times the transformation ratio.

- There is 30° shift between the primary and secondary line voltages.

Υ – Δ (Star – Delta ) Connection (OR Wye-Delta)

- The primary winding is star star (Y) connected with grounded neutral and the secondary winding is delta connected.

- This connection is mainly used in step down transformer at the substation end of the transmission line.

- The ratio of secondary to primary line voltage is 1/√3 times the transformation ratio.

- There is 30° shift between the primary and secondary line voltages.

Three-phase Transformer Line Voltage and Current

| Primary-Secondary Configuration |

Line Voltage Primary or Secondary |

Line Current Primary or Secondary |

| Delta – Delta |

|

|

| Delta – Star |

|

|

| Star – Delta |

|

|

| Star – Star |

|

|

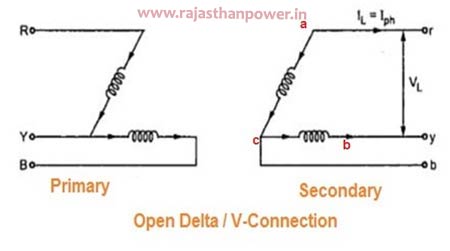

Open Delta (V-V) Connection

Open delta association can be utilized when one of the transformers in Δ-Δ bank is debilitated and the benefit is to be proceeded until the defective transformer is repaired or supplanted. It can too be utilized for little three phase loads where establishment of full three transformer bank is un-necessary.

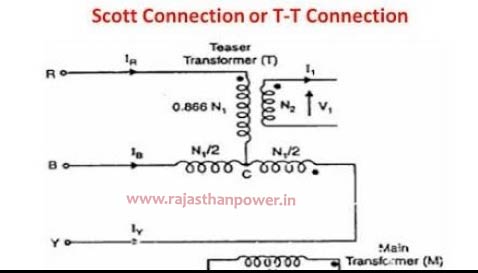

Scott (T-T) Connection

Two transformers are utilized in this type of association. One of the transformers has middle taps on both essential and auxiliary windings (which is called as primary transformer). The other transormer is called as teaser transformer. Scott connection can moreover be utilized for three phase to two phase transformation.

three phase auto transformer connection diagram

For Final Three Phase transformer price India Please Mail Us on info@rajasthanpower.in

6kva transformer 3 phase

3 phase step down transformer

3 phase 110v transformer

Are you looking for small 3 phase transformer, single phase to Three Phase converter transformer ? check 3 phase auto transformer price.

well , when we conversation approximately 3 phase , we mean 3 conductors having same potential but with diverse phases ( , 120 , 240 ) . Any 3 phase circuit would be total as it were when it features a return way , thus a forth conductor comes to picture , say it neutral .so also for 1 phase , we require 1 conductor and one neutral .So in case we need 1 phase from a 3 phase supply , we might fair take one conductor out of 3 equi-potential conductors from 3 phase beside neutral .

Basically , for transmission of control we utilize delta connection ( which cannot be utilized to form a neutral ) . While for dissemination of power star connection is utilized , which can be utilized to induce a neutral . So essentially one should have a 3 phase supply from a star connection with a neutral to change over into 1 phase . Isolation transformer that converts three phase voltage 400 V to single phase voltage 230 V. Single-phase voltage 230V permits to supply equipments at three-phase establishments without neutral. The three to single-phase transformer permits an amazing conveyance of the power retained by a single-phase load on all three phases.

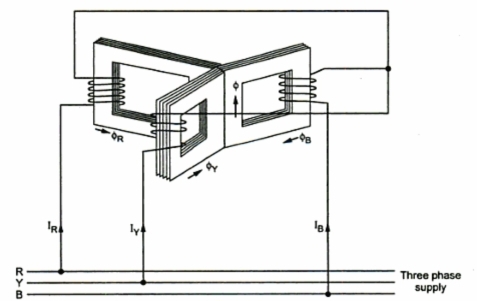

Consider the underneath figure in which the primary of the transformer is associated in star fashion on the cores. For straightforwardness, as it were essential winding is appeared within the figure which is associated over the three phase AC supply. The three cores are organized at an point of 120 degrees to each other. The empty leg of each core is combined in such that they shape center leg as appeared in figure.

When the essential is energized with the three phase supply source, the currents IR, IY and IB are begins streaming through person phase windings. These currents create the magnetic fluxes ΦR, ΦY and ΦB within the particular cores.Likewise, in three phase framework where any two conductors acts as return for the current in third conductor, any two legs acts as a return way of the flux for the third leg in case the center leg is evacuated in case of three stage transformer. In this manner, whereas designing the three phase transformer, this rule is used.

Let,

N1 = Number of turns in primary winding

N2 = Number of turns in secondary winding

Φm = Maximum flux in the core (in Wb) = (Bm x A)

f = frequency of the AC supply (in Hz)

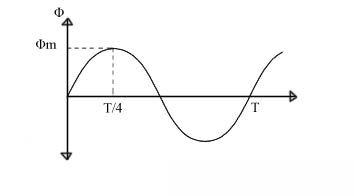

As, shown in the fig., the flux rises sinusoidally to its maximum value Φm from 0. It reaches to the maximum value in one quarter of the cycle i.e in T/4 sec (where, T is time period of the sin wave of the supply = 1/f).

Therefore,

average rate of change of flux = Φm /(T/4) = Φm /(1/4f)

Therefore,

average rate of change of flux = 4f Φm ……. (Wb/s).

Now,

Induced emf per turn = rate of change of flux per turn

Therefore, average emf per turn = 4f Φm ……….(Volts).

Now, we know, Form factor = RMS value / average value

Therefore, RMS value of emf per turn = Form factor X average emf per turn.

As, the flux Φ varies sinusoidally, form factor of a sine wave is 1.11

Therefore, RMS value of emf per turn = 1.11 x 4f Φm = 4.44f Φm.

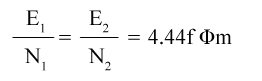

RMS value of induced emf in whole primary winding (E1) = RMS value of emf per turn X Number of turns in primary winding

E1 = 4.44f N1 Φm ……………………….. eq 1

Similarly, RMS induced emf in secondary winding (E2) can be given as

E2 = 4.44f N2 Φm. ………………………. eq 2

from the above equations 1 and 2,

This is called the emf equation of transformer, which shows, emf / number of turns is same for both primary and secondary winding.

For an ideal transformer on no load, E1 = V1 and E2 = V2 .

where,

- V1 = supply voltage of primary winding

- V2 = terminal voltage of secondary winding

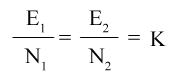

Voltage Transformation Ratio (K)

As derived above,

Where, K = constant

This constant K is known as voltage transformation ratio.

- If N2 > N1, i.e. K > 1, then the transformer is called step-up transformer.

- If N2 < N1, i.e. K < 1, then the transformer is called step-down transformer.

Materials

In the AC Magnetic analysis of EMS, the whole properties of material are needed (Table 1).

| Components / Bodies | Material | Relative permeability | Conductivity (S/m) |

| Inner Coil / Outer coil | Copper | 0.99991 | 57e+006 |

| Outer Air / Inner Air | Air | 1 | 0 |

Electromagnetic Input

3 primary coils and 3 secondary coils (Table 2) are applied. The AWG is specified in EMS coil definition, it’s, in this case, 38.06150 and the wire diameter of the coil is 0.10001348 mm.

| Name | Number of turns | Magnitude | Phase |

| Wound Coil 1 (primary) | 300 | 1 A | 0 |

| Wound Coil 2 (primary) | 300 | 1 A | 120 deg |

| Wound Coil 3 (primary) | 300 | 1 A | 240 deg |

| Wound Coil 1 (secondary) | 300 | 0 A | 0 |

| Wound Coil 2 (secondary) | 300 | 0 A | 120 deg |

| Wound Coil 3 (secondary) | 300 | 0 A | 240 deg |

three phase transformer load test

Transformer is an electrical hardware which exchanges electrical power from one circuit to another circuit through magnetic areas. Within the ship electrical framework, unbalanced load on the three-phase of transformer is regularly found. It is due to the load operational time which does not happen at the same time. In case the unequal load happens continuously on the transformer, it’ll diminish the transformer’s execution. This inquire about points to test the three-phase transformer input 61-103 on the different connection winding in marine electrical and mechanization research facility framework.

It was conducted by collecting the information to induce the results of proficiency, voltage direction, and unbalanced load calculation to discover out the impact of unbalanced load to the execution of each transformer winding. From the results of the test, the highest productivity was 93.8% within the wye-Zigzag wye connection winding and delta-connected load. The least voltage direction was 0.9% within the wye-delta connection winding and wye-connected load and delta-connected load. The most reduced unequal load was 5.0% within the delta-delta connection winding and wye-connected load.

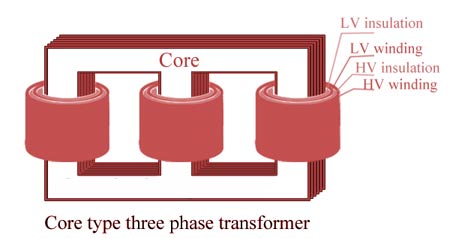

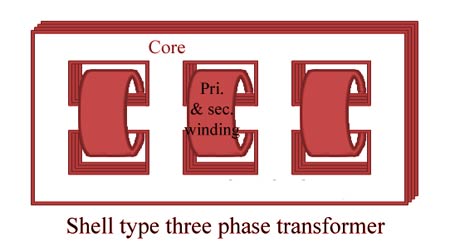

Three phase transformers can be of core type or shell type (just like single phase transformers).

Core Type Construction

The construction of a core type three phase transformer is as appeared within the figure. The core comprises of three legs or limbs. As normal, the core is made up of lean covered sheets to reduce eddy current misfortunes. Each limb has essential and auxiliary windings in round and hollow shape (former wound) organized concentrically.

Shell Type Construction

In a shell type three phase transformer, three phases are more autonomous than they are in core type. Each phase has its individual magnetic circuit. The construction of shell type three phase transformer is outlined within the figure at below. The construction is comparative to that of three single phase shell type transformers kept on the best of each other.

Three Phase Transformers Advantages

- It is lighter and smaller.

- It requires less space to install.

- Low cost compared with three units of single phase transformers.

- Being prewired and ready to install, these can be easier to install.

- Only three terminals are required to be brought out in case of a three phase transformer compared to six terminals from three single phase transformers.

- Bus bar structure and switchgear installation for single three phase unit is simpler.

- Higher efficiency

- To provide the same KVA, the core material required is very less compared to a bank of three single phase transformers.

- Transportation is easy and also transportation cost is less.

Disadvantages of Three Phase Transformers

- When these are self cooled, the capacity of the transformer is reduced.

- To restore the service, spare unit cost is more compared with one single transformer spare unit.

- Cost of repair is more for three phase transformer.

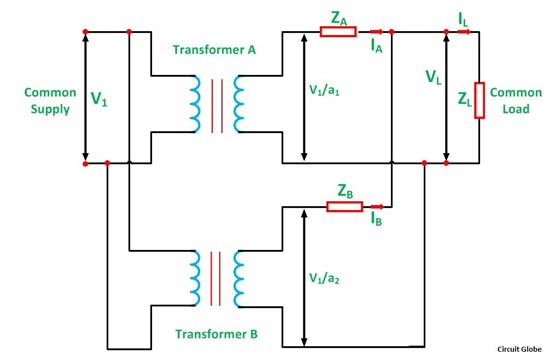

Parallel operation of three phase transformer is exceptionally common in three phase power generation, transmission and distribution. It is invaluable to utilize two or more Transformer units in parallel rather than employing a single huge unit. This offers adaptability for upkeep as well as operation.

Condition for Parallel Operation of Three Phase Transformers

- The transformers should have the same polarity.

- The transformers should have equal per unit leakage impedance. (You may read per unit system)

- The ratio of equivalent leakage reactance to equivalent resistance should be same for all the transformers.

- The line voltage ratio of the transformers must be same.

The above four conditions are also applicable for parallel operation of single phase transformers

Parallel Operation of Three Phase Transformers Advantages

- It increases the reliability of supply system

- The size of transformer increases with the increase of its rating

- The maintenance opportunity in case of parallel operation is increments. One or more transformers may be taken beneath maintenance whereas the remaining transformers will supply the load at decreased power.

- Three Phase transformers are widely used as Power transformers

- Distribution transformers

- in Electrical Grids.

- Some loads such as industrial, and commercial require 3 phase transformers to meet their demand.

Rating of a Three Phase Transformer:

P = √3. V x I

Rating of a Three phase transformer in kVA:

kVA = (√3. V x I) /1000

Typical Insulation Resistance Values for Power and Distribution Transformers

| Transformer Winding Voltage (kV) | Winding Ground (MΩ) | ||||

| 22°C | 30°C | 40°C | 50°C | 60°C | |

| 6.6 | 400 | 200 | 100 | 50 | 25 |

| 6.6 – 19 | 800 | 400 | 200 | 100 | 50 |

| 22 – 45 | 1000 | 500 | 250 | 125 | 65 |

| ≥ 66 | 1200 | 600 | 300 | 100 | 75 |

Transformer Insulation Resistance Acceptance Testing

| Winding Insulation Class, kV | Insulation Resistance, MΩ* |

| 1.2 | 600 |

| 2.5 | 1000 |

| 5.0 | 1500 |

| 8.7 | 2000 |

| 15 | 3000 |

Insulation Resistance Test Procedure:

- Disconnect the equipment, apply working grounds to all approaching and outgoing cables and disengage all approaching and active cables from the transformer bushing terminals connections. Detached cables should have sufficient clearance from the switchgear terminals more prominent that the phase spacing distance. Utilize nylon rope to hold cable absent from approaching and outgoing terminals as required.

- Ensure the transformer tank and core is grounded.

- Disconnect all lightning fan system, arresters, meter or low voltage control systems that are connected to the transformer winding.

- Short circuit all winding terminals of the same voltage level together.

- Perform a 1 minute resistance measurements between each winding group to the other windings and ground.

- Remove all shorting leads after completion of all test.

| Transformers, Full Load Amperes (FLC) | ||||

| KVA | 208V | 240V | 480V | 600V |

| 3 | 8.3 | 7.2 | 3.6 | 2.9 |

| 6 | 16.6 | 14.4 | 7.2 | 5.8 |

| 9 | 25 | 21.6 | 10.8 | 8.6 |

| 15 | 41.7 | 36.1 | 18.0 | 14.4 |

| 30 | 83.4 | 72.3 | 36.1 | 28.9 |

| 45 | 124 | 108 | 54.2 | 43.4 |

| 75 | 208 | 180 | 90 | 72 |

| 112.5 | 312 | 270 | 135 | 108 |

| 150 | 416 | 360 | 180 | 144 |

| 225 | 624 | 541 | 270 | 216 |

| 300 | 832 | 721 | 360 | 288 |

| 500 | 1387 | 1202 | 601 | 481 |

| 750 | 2084 | 1806 | 903 | 723 |

| 1000 | 2779 | 2408 | 1204 | 963 |

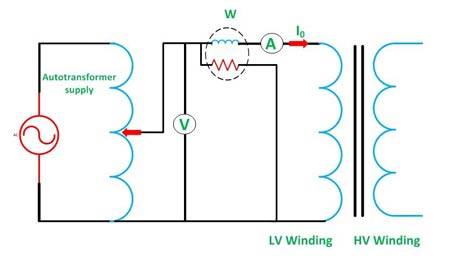

Open Circuit Test

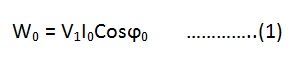

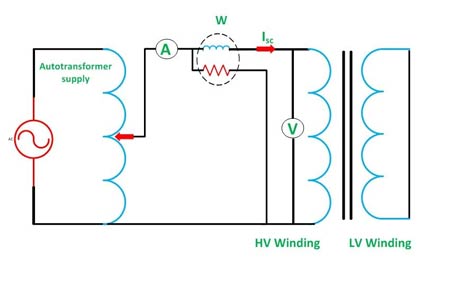

Open circuit test or no load test on a transformer is performed to decide ‘no load misfortune (core loss)’ and ‘no load current I0’. The circuit graph for open circuit test is appeared within the figure below.Usually high voltage (HV) winding is kept open and the low voltage (LV) winding is associated to its ordinary supply. A wattmeter (W), ammeter (A) and voltmeter (V) are connected to the LV winding as appeared within the figure. Presently, connected voltage is gradually expanded from zero to normal rated esteem of the LV side with the assistance of a variac. When the connected voltage comes to to the evaluated esteem of the LV winding, readings from all the three disobedient are taken.

Calculation of open circuit test

Let,

- W0 – wattmeter reading

- V1 – voltmeter reading

- I0 – ammeter reading

Then the iron loss of the transformer Pi = W0 and

Short Circuit Or Impedance Test On Transformer

The short circuit test is performed on the secondary or high voltage winding of the transformer. The measuring instrument like wattmeter, voltmeter and ammeter are associated to the High voltage winding of the transformer. It decides the copper loss happen on the total load. The copper loss is utilized for finding the productivity of the transformer.The comparable resistance, impedance, and leakage reactance are known by the short circuit test.Their primary winding is shortcircuited by the assistance of thick strip or ammeter which is associated to their terminal.

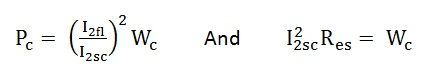

Calculation of Short Circuit Test

Let,

- Wc – Wattmeter reading

- V2sc – voltmeter reading

- I2sc – ammeter reading

Then the full load copper loss of the transformer is given by

Equivalent resistance referred to secondary side is

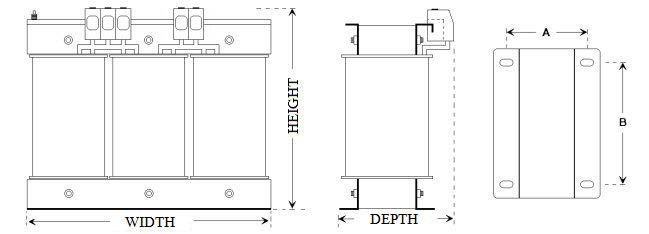

| POWER (VA) | CODE | HEIGHT (MM) | WIDTH (MM) | DEPTH (MM) | A (MM) | B (MM) | WEIGHT (KG) |

|---|---|---|---|---|---|---|---|

| 250 | TTM250N1 | 175 | 180 | 110 | 65 | 150 | 6,0 |

| 330 | TTM330N1 | 175 | 180 | 120 | 75 | 150 | 75 |

| 420 | TTM420N1 | 175 | 180 | 130 | 85 | 150 | 9,0 |

| 500 | TTM500N1 | 175 | 180 | 140 | 95 | 150 | 10,5 |

| 660 | TTM660N1 | 175 | 180 | 155 | 110 | 150 | 13,5 |

| 800 | TTM800N1 | 225 | 240 | 130 | 85 | 200 | 14,0 |

| 1.000 | TTM1K1N1 | 225 | 240 | 140 | 95 | 200 | 18,0 |

| 1.250 | TTM1K25N1 | 225 | 240 | 140 | 95 | 200 | 18,5 |

| 1.650 | TTM1K65N1 | 225 | 240 | 165 | 120 | 200 | 24,0 |

| 2.100 | TTM2K1N1 | 225 | 240 | 165 | 120 | 200 | 25,5 |

| 2.500 | TTM2K5N1 | 285 | 300 | 140 | 95 | 250 | 28,5 |

| 3.350 | TTM3K35N1 | 285 | 300 | 150 | 105 | 250 | 34,5 |

| 4.200 | TTM4K2N1 | 285 | 300 | 160 | 115 | 250 | 39,0 |

| 5.000 | TTM5KN1 | 285 | 300 | 170 | 125 | 250 | 44,0 |

| 5.800 | TTM5K8N1 | 350 | 360 | 140 | 105 | 280 | 53,5 |

| 6.700 | TTM6K7N1 | 350 | 360 | 140 | 105 | 280 | 56,0 |

| 7.500 | TTM7K5N1 | 350 | 360 | 150 | 115 | 280 | 61,5 |

| 8.350 | TTM8K35N1 | 350 | 360 | 160 | 125 | 280 | 67,5 |

| 11.000 | TTM11KN1 | 350 | 360 | 180 | 145 | 280 | 82,5 |

| 12.500 | TTM12K5N1 | 350 | 360 | 190 | 155 | 280 | 88,5 |

|

|