dry type transformer manufacturer in india

Prestige Quality cast resin dry type transformer suppliers in africa, view dry type transformer price

Rajasthan Powergen Transformer P. Ltd. is a dry type transformer manufacturer in India. Dry type transformers don’t use any liquids for insulation. Regular transformers operate with an insulating liquid where the core is immersed in it. The dry type transformers use a different technique and use a pressurized container surrounded by air. The core is kept inside the pressurized container.

dry type transformer manufacturer in india

cast resin dry type transformer

dry type distribution transformer

World-Class 2000 kva dry type transformer, dry type distribution transformer, 500 kva dry type transformer Exporter in india

A dry type distribution transformer could be used in industries such as Renewable energy generation such as wind power, Inner urban stations, indoor and underground stations, fire risky areas, chemical, oil and gas industries and some environmentally sensitive areas.

Types and models of dry type distribution transformers

There are two types of three phase dry type transformers; Cast Resin Dry Type Transformer (CRT) and Vacuum pressure Impregnated Transformer (VPI). depending on the capacity there are different models such as 25 kva dry type transformer, 100 kva dry type transformer, 500 Kva Dry Type Transformer, 1000 kva dry type transformer, 1500 kva dry type transformer, and 2000 Kva Dry Type Transformer.

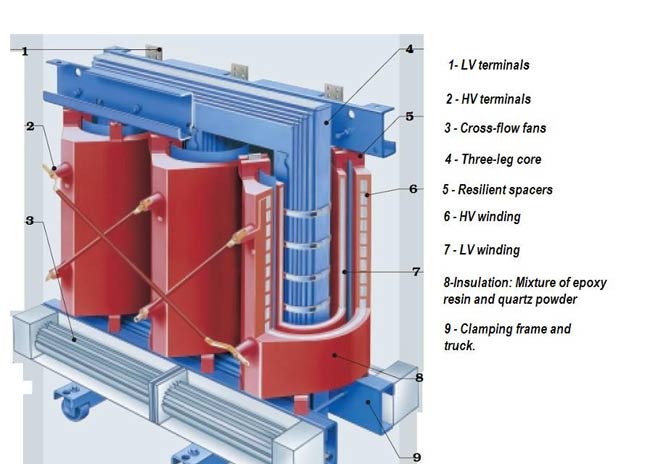

The cast resin type has the primary and secondary coil windings encapsulated with epoxy resin. This means high resistance to moisture prone environments. This special property or characteristic is called non hygroscopic. They can be fitted in IP 45 enclosure in an outdoor environment. They have a higher efficiency due to the low partial discharge and low loss. All of these result in better overload capacity as well.

Dry type power transformer is a bit costlier than the other types for same power and voltage rating. Also if there is a winding failure during operation, say in an outdoor dry type transformer, the high voltage and low voltage windings along with the limb have to be changed.

Advantages of dry cast resin transformers

They are very safe for properties nearby and the people who operate them and around them. They are well suited for contaminated and damp areas. They have excellent resistance to short circuiting electricity. They are easy to install, environmentally friendly, maintenance and pollution free, not fire hazardous, and the side clearance is very less. They also long last with the low thermal heating and dielectric heating. Dry type power transformer operates with excellent performance even in seismic events due to the absence of liquid inside. Although these are expensive their cost of installation in civil and fire protections systems is very low. They support overloads very effectively.

Rajasthan Powergen Transformer P. Ltd. is a proud dry type transformer manufacturer in India.

A dry type transformer could be a type of transformer which never employments any protection fluid where its winding or center are immerged in fluid. Or maybe, the windings and core are kept inside a fixed tank that’s pressurized with air.Dry sort transformers require minimum upkeep to supply numerous a long time of solid inconvenience free benefit. A dry-type transformer has no moving parts and may be a totally inactive strong state gadget, beneath ordinary working conditions, are usually guaranteed a long and trouble-free life. Dry type transformers give a secure and solid power source which does not require fire proof vaults, capture basins or the venting of harmful gasses.

Types of Dry Type Transformers

The dry type transformer types. They are

- Cast Resin Dry Type Transformer (CRT)

- Vacuum pressure Impregnated Transformer (VPI)

- Vacuum Pressure Encapsulated (VPE)

- Cast Coil

- Open Wound Transformer

| dry type transformer Rating | Upto 3mVA |

| Duty Type | Outdoor/Indoor, Ground Mounted Type& Pole Mounted Type |

| dry type transformer Voltage Class | Upto 33Kv |

| No Of Phases | 3 phase |

| Frequency | 50/60 Hz |

| dry type transformer Vector Group | Dyn1 or Dyn5 or Drn11 or any specific |

| Class Of Insulation | F , H Or C class as required |

| Idry type transformer nsulating Material | Nomex, Silicone Varnish, Fiber Glass, Glass Epoxy |

| Class Of Insulation | Class A |

| dry type transformer Tap Changer | Off Circuit or On Load |

| dry type transformer Temperature Rise | 65.C to 115.C above ambient temperature of 50.C by resistance method or as per customer’s requirement |

| Tap Changer | Off Circuit or On Load |

| Tapping Range | +-2.5% X 2 for OCTC or +-2.5% X 2 & -2.5% X6 for OLTC as per customer requirement |

| dry type transformer Winding Material | Aluminum Or Copper with multi paper NOMEX covering |

| Applicable Standards | IS 11171,IEC 60726 |

| dry type transformer Enclosure Painting | Powder Coated with RAL 7032 Shade or as per customer requirement |

| dry type transformer manufacturers india Export to | Nepal, Nigeria, Africa, Malaysia Tanzania, Kenya, Rwanda, Uganda, India, Bangladesh, Malawi, |

| Tank | Hermetically Sealed, Corrugated Type or Conventional Air cooled Type |

For Final cast resin dry type transformer price india Please Mail Us on info@rajasthanpower.in

Request A Quote Today For dry type power transformer, outdoor dry type transformer, dry cast resin transformers, view 1000 kva dry type transformer and 100 kva dry type transformer price

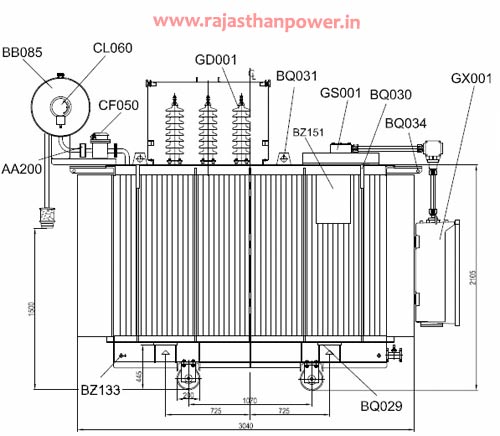

follwing Fig. shows dry type transformer Design

Advantages of Dry Type Transformer

The main advantages of dry type transformer are given below.

- Side clearance is less.

- Reduced cost on civil installation works and fire protection systems.

- Safety for people and property.

- Excellent resistance to short circuit currents.

- Environmentally friendly.

- Easy installation.

- Maintenance and pollution-free solution.

- Suited for damp and contaminated areas.

- Excellent capacity to support overloads.

- Excellent performance in case of seismic events.

- Long lasting due to low thermal and dielectric heating.

- No fire hazard.

Disadvantages of Dry Type Transformer

But there are some disadvantages of dry type transformer. They are-

- For same power and voltage rating, dry type transformer is costlier than oil cooled transformer.

- Dry type transformer is long enduring and with less chance of winding disappointment. But once it comes up short entirety set up is to changed, i.e. total alter of high voltage and low voltage winding with limb.

Dry-type transformers are available in three general classes of insulation. The fundamental highlights of insulation are to supply dielectric strength and to be be able to resist certain thermal limits. Insulation classes are:

- 220°C (Class R) dry type transformer

- 180°C (Class H) dry type transformer

- 155°C (Class F) dry type transformer

- 130°C (Class B) dry type transformer

- 105°C (Class A) dry type transformer

- No Partial Discharge, as max voltage appearing at any part of the winding is limited to the turn to turn

- Better monitoring of hot spot temperature

- Does not emit toxic and blinding smoke in the event of a fire

- Higher resistance to Short circuit forces using Disc wound coils having self – locking property

- No trapped mechanical forces, improving the thermal operation

- Maximum creepage available in coils

- Maximum heat dissipation

- Maintenance free

- Least amount of combustible materials

Standard accessories of dry type transformer

- 2 or 4 lifting lugs (according to the rating power)

- 2 grounding terminals

- 4 bidirectional wheels

- 1 identification plate

- Tapping terminal board on MV side

- Threaded pins provided with bolt for MV terminal connection

- 4 connections for haulage

All transformers are tested in compliance with IEC 60076-1 and IEC 60076-11

Below the list of routine tests to be performed on dry-type transformers:

- Dielectric routine tests (please check below according to the Um (IEC 60076-3))

- Tests on on-load tap changers, where appropriate

- Measurement of winding resistance

- Auxiliary wiring insulation test

- Measurement of no-load loss and current

- Measurement of short-circuit impedance and load loss

- Measurement of voltage ratio

- Checking of phase displacement

- Measurement of partial discharges

- Check of the ratio and polarity of built-in transformers

- Insulation test and functional verification of accessories

Type tests of dry type transformer

Below the list of type tests to be performed on dry-type transformers:

- Determination of sound level (IEC 60076-10) for each method of cooling for which a guaranteed sound level is specified

- Dielectric type tests (IEC 60076-3)

- Temperature-rise type test (IEC 60076-2)

- Measurement of no-load loss and current at 90% and 110% of rated voltage

- Measurement of the power taken by the fan

Special tests of dry type transformer

Below the list of special tests that can be performed on dry type transformers directly in SEA or in our associated laboratories:

- Measurement of dissipation factor (tan δ) of the insulation system capacitances

- Winding hot-spot temperature-rise measurements

- Dielectric special tests (IEC 60076-3)

- Determination of capacitances windings-to-earth and between windings

- Short-circuit withstand test

- Determination of transient voltage transfer characteristics

- Measurement of zero-sequence impedance(s) on three phase transformers

- Measurement of frequency response (Frequency Response Analysis or FRA); the test procedure shall be agreed between manufacturer and purchaser

- Measurement of d.c. insulation resistance between each winding to earth and between windings

- Detection of harmonic content in no load current

- Measurement of winding inductance

- Determination of weight with transformer arranged for transport for transformers up to 1,6 MVA by measurement; for larger transformers by measurement or calculation as agreed between manufacturer and purchaser

- Check of external coating (ISO 2178 and ISO 2409 or as specified)

- Thermographic detection of hot-spots

- Verification of the behaviour to fire classes

- Measurement of the transmitted vibrations

- Verification of the climatic classes

- In-rush surges test

- Verification of the environmental classes

- Test on vibration floor (seismic)

- Recurrent voltage surges test

- Low temperature test

Other tests requirements for specific transformers are specified in IEC 60076-3

Archive of type tests

SEA has a large archive of type and special tests carried out on many dry-type transformers that can be consulted by its customers.

Some examples of test performed on cast resin transformers:

-

Various tests on insulating materials

Samples made of the same used resin for the autoestinguishing test have been analized by IMQ. -

Fire behaviour test performed by CESI

This test has been carried out on a sample composed by a complete leg (core, LV and HV windings) of a 1600 kVA transformers. - Toxicity tests by Breda Scientific Institute

In compliance with the test methods provided by CEI 20-37 on a cast resin sample, a toxicity percentage lower than 0.1% has been recorded for gases released during combustion. - Low temperature tests

Thermal cycle test has been carried out and passed at CESI (4 cycles from -20 °C to +20 °C in 24 hours).

Thermal shock test at -50 °C has been carried out and passed at Magrini’s lab. - Dynamic short circuit withstand test

Several certificates of dynamic short circuit tests carried out on transformers with different powers and voltages have been performed at CESI.

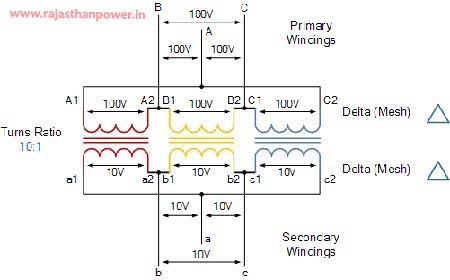

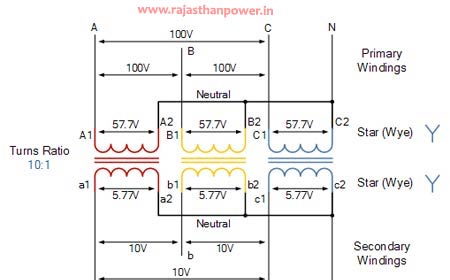

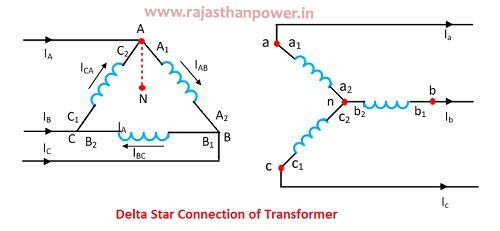

The dry type transformer comprises three transformers either isolated or combined with one core.There are four conceivable connections for a dry type transformer bank.

- Δ – Δ (Delta – Delta) Connection for dry type transformer

- Υ – Υ (Star – Star) Connection for dry type transformer

- Δ – Υ (Delta – Star) Connection for dry type transformer

- Υ – Δ (Star – Delta ) Connection for dry type transformer

dry type transformer Winding Identification

| Connection | Primary Winding | Secondary Winding |

| Delta | D | d |

| Star | Y | y |

| Interconnected | Z | z |

dry type transformer Delta-Delta (Δ-Δ) Connection :

- This connection is generally used for large, low-voltage transformers. Number of required phase/turns is relatively greater than that for star-star connection.

- The ratio of line voltages on the primary and the secondary side is equal to the transformation ratio of the transformers.

- This connection can be used even for unbalanced loading.

dry type transformer Υ – Υ (Star – Star) Connection

- Star-star connection is generally used for small, high-voltage transformers. Because of star connection, number of required turns/phase is reduced (as phase voltage in star connection is 1/√3 times of line voltage only). Thus, the amount of insulation required is also reduced.

- The ratio of line voltages on the primary side and the secondary side is equal to the transformation ratio of the transformers.

- Line voltages on both sides are in phase with each other.

dry type transformer Δ – Υ (Delta – Star) Connection(OR Delta-Wye (Δ-Y))

- The primary winding is connected in delta and the secondary winding is connected in star with neutral grounded. Thus it can be used to provide 3-phase 4-wire service.

- This type of connection is mainly used in step-up transformer at the beginning of transmission line.

- The ratio of secodary to primary line voltage is √3 times the transformation ratio.

- There is 30° shift between the primary and secondary line voltages.

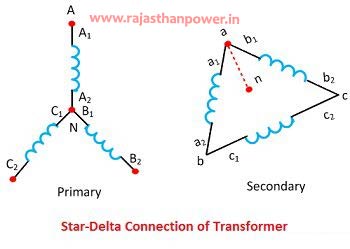

dry type transformer Υ – Δ (Star – Delta ) Connection (OR Wye-Delta)

- The primary winding is star star (Y) connected with grounded neutral and the secondary winding is delta connected.

- This connection is mainly used in step down transformer at the substation end of the transmission line.

- The ratio of secondary to primary line voltage is 1/√3 times the transformation ratio.

- There is 30° shift between the primary and secondary line voltages.

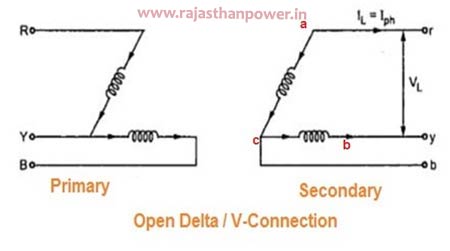

dry type transformer Open Delta (V-V) Connection

Open delta association can be utilized when one of the transformers in Δ-Δ bank is debilitated and the benefit is to be proceeded until the defective transformer is repaired or supplanted. It can too be utilized for little three phase loads where establishment of full three transformer bank is un-necessary.

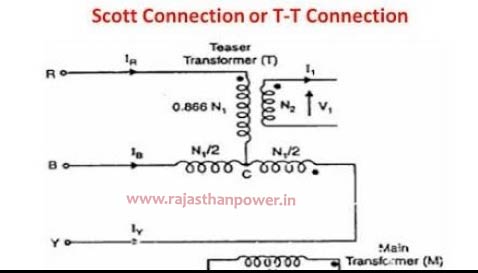

dry type transformer Scott (T-T) Connection

Two transformers are utilized in this type of association. One of the transformers has middle taps on both essential and auxiliary windings (which is called as primary transformer). The other transormer is called as teaser transformer. Scott connection can moreover be utilized for three phase to two phase transformation.

Three-Phase Transformer Line Voltage And Current

| Primary-Secondary Configuration |

Line Voltage Primary or Secondary |

Line Current Primary or Secondary |

| Delta – Delta |

|

|

| Delta – Star |

|

|

| Star – Delta |

|

|

| Star – Star |

|

|

| dry type transformer | oil type transformer |

| Air is worse insularion than oil. So the dry TR’s rated voltage is limited up to 35kV (66kV dry TR had been finished in lab, but not be lauched.) | Oil TR canreach very high voltage, even 1000kV. |

| Dry TR just have one temperature monitor. | Oil TR have oil tank to save oil and winding&core. There are more sensors to monitor temperature, pressure, oil level, oil humidity and gas flow and also some safe device to avoid explode. |

| Dry TR is larger and lower efficiency generally, because same insulation level requires larger air gap than oil gap. | From fire behavious, oil TR is more danger because oil is flamble material and easy flow in site. |

The type of assurance gadget utilized will depend on criteria such as coherence and quality of benefit, fetched of speculation and operation and security of property and individuals as well as the satisfactory level of chance. The arrangements chosen are continuously a compromise between the different criteria.

8 important checks to do before powering up the dry-type transformer for protection

- Check name plate ratings

- Check parallel operation

- Check connections: cables, bus bars

- Check tap change connections

- Check grounding connection

- Check thermal protective device

- Check impurities removal

- Check insulation resistance test

For an expanded life and ideal execution of your dry-type transformer, support activities are profoundly suggested on a occasional premise.

- Firstly, de-energize the dry type transformer, do not do anything before the dry type transformer is completely de-energized.

- After ensuring the complete de-energization of the dry type transformer, remove all the panels both external and internal which have accumulated dust.

- Use a vacuum system to efficiently remove all the dust build-up, this majorly helps in cleaning small, detailed parts.

- If some part of the dry type transformer cannot be removed or is intricately located, blow dry air into the unit, it will clean the accumulated dust.

- Do not use any cleaning products apart from a lint-free cloth to clean the transformer.

- Dry type transformer does not need proper cleaning every day, so when the dust is visible on the outer parts of the dry type transformer as per your subjective observations, routine dust clean up can be started.

Minimum Power Efficiency Levels For Dry Type Transformer

|

Type |

kVA |

Power efficiency @ 50% load |

|

|---|---|---|---|

|

|

Um=12kV |

Um=24kV |

|

|

Single phase (and SWER) |

10 |

97.29 |

97.01 |

|

16 |

97.60 |

97.27 |

|

|

25 |

97.89 |

97.53 |

|

|

50 |

98.31 |

97.91 |

|

|

Three phase |

25 |

97.17 |

97.17 |

|

63 |

97.78 |

97.78 |

|

|

100 |

98.07 |

98.07 |

|

|

200 |

98.46 |

98.42 |

|

|

315 |

98.67 |

98.59 |

|

|

500 |

98.84 |

98.74 |

|

|

750 |

98.96 |

98.85 |

|

|

1000 |

99.03 |

98.92 |

|

|

1500 |

99.12 |

99.01 |

|

|

2000 |

99.16 |

99.06 |

|

|

2500 |

99.19 |

99.09 |

|

NOTE: For intermediate power ratings the power efficiency level shall be calculated by linear interpolation.

High Power Efficiency Levels For Dry-Type Transformers

|

Type |

kVA |

Power efficiency @ 50% load |

|

|---|---|---|---|

|

|

Um=12kV |

Um=24kV |

|

|

Single phase (and SWER) |

10 |

97.53 |

97.32 |

|

16 |

97.83 |

97.55 |

|

|

25 |

98.11 |

97.78 |

|

|

50 |

98.50 |

98.10 |

|

|

Three Phase |

25 |

97.42 |

97.42 |

|

63 |

98.01 |

98.01 |

|

|

100 |

98.28 |

98.28 |

|

|

200 |

98.64 |

98.60 |

|

|

315 |

98.82 |

98.74 |

|

|

500 |

98.97 |

98.87 |

|

|

750 |

99.08 |

98.98 |

|

|

1000 |

99.14 |

98.04 |

|

|

1500 |

99.21 |

99.12 |

|

|

2000 |

99.24 |

99.17 |

|

|

2500 |

99.27 |

99.20 |

|

Open Wound Transformers

The conductor coils are pre-heated and after that heated, dipping them in varnish at an lifted temperature. These coils are then baked to remedy the varnish. Typically called the dip-and-bake strategy.

VPI transformers are built with high-temperature cover and are comprised of high-temperature materials coated with high-temperature, moisture-resistant and polyester sealants using a vacuum pressure impregnation process.

These are comparative to VPI transformers, only that the polyester sealant is supplanted by resin made of silicone. The make of these transformers includes a few dip forms, followed by curing the coating in an oven. Too, the resin coating in these transformers is as much as four times that of polyester in VPI transformers. VPE transformers are exceedingly resistant to sticky and caustic situations and the impacts of salt water.

Cast Coil Resin Transformers

The conductor coils are firmly cast in resin beneath vacuum in a form with indeed dispersion and high level of accuracy. These transformers are solid and can be uncovered to extraordinary conditions. They require minimum upkeep and can withstand high brief circuits. Usually the reason these cast coil resin transformers are presently being utilized where prior only liquid-filled units were accessible for unforgiving situations. These transformers today are profoundly utilized in tunnels, ships, cranes, nuclear plants and mining businesses.

More another types of dry type transformer

- Three Phase Dry Type Transformers

- 415 V Dry Type Transformers

The cast resin dry type transformers are designed and tested to comply with national & international standards such as IEC 60726, IS 11171, NEMA, ANSI and Australian Standard.

No transformer is really an ‘ideal transformer’ and thus each will bring about a few misfortunes, most of which get changed over into warm. If this warm isn’t scattered appropriately, the overabundance temperature in transformer may cause genuine issues like insulation failure. It is clear that transformer needs a cooling framework.

dry type transformer can be divided in two types as

(i) dry type transformers and

(ii) oil immersed transformers.

Different cooling methods of dry type transformer are –

- For dry type transformers

- Air Natural (AN)

- Air Blast

- For oil immersed tranformers

- Oil Natural Air Natural (ONAN)

- Oil Natural Air Forced (ONAF)

- Oil Forced Air Forced (OFAF)

- Oil Forced Water Forced (OFWF)

- Oil and Water cooling (For capacity more than 30MVA)

- Oil Natural Water Forced (ONWF)

- Oil Forced Water Forced (OFWF)

| Type | Rated capacity (kVA) | No-load loss (W) | Loading loss (W/75 °C) | No-Load current (%) | Sound level (dB) | Impedance voltage (%) | Base gauge (mm) | Weight (kg) | Outer dimension mm (L × W × H) |

|---|---|---|---|---|---|---|---|---|---|

| SC10-50/10 | 50 | 270 | 870 | 2.1 | 43 | 4 | 550 | 460 | 1010 × 610 × 930 |

| SC10-80/10 | 80 | 360 | 1200 | 1.8 | 45 | 4 | 550 | 630 | 1010 × 610 × 960 |

| SC10-100/10 | 100 | 400 | 1370 | 1.8 | 45 | 4 | 550 | 690 | 1010 × 610 × 980 |

| SC10-160/10 | 160 | 540 | 1850 | 1.6 | 45 | 4 | 550 | 920 | 1180 × 880 × 1055 |

| SCB10-200/10 | 200 | 620 | 2220 | 1.4 | 46 | 4 | 660 | 1130 | 1320 × 760 × 1085 |

| SCB10-250/10 | 250 | 720 | 2420 | 1.4 | 46 | 4 | 660 | 1280 | 1320 × 760 × 1155 |

| SCB10-315/10 | 315 | 890 | 3040 | 1.2 | 46 | 4 | 660 | 1390 | 1320 × 760 × 1155 |

| SCB10-400/10 | 400 | 980 | 3500 | 1.2 | 48 | 4 | 660 | 1760 | 1380 × 760 × 1315 |

| SCB10-500/10 | 500 | 1170 | 4290 | 1.2 | 48 | 4 | 660 | 2040 | 1380 × 760 × 1365 |

| SCB10-630/10 | 630 | 1350 | 5160 | 1.0 | 50 | 4 | 660 | 2200 | 1420 × 760 × 1410 |

| SCB10-630/10 | 630 | 1300 | 5240 | 1.0 | 50 | 6 | 660 | 2390 | 1450 × 760 × 1435 |

| SCB10-800/10 | 800 | 1530 | 6100 | 1.0 | 50 | 6 | 820 | 2570 | 1600 × 970 × 1480 |

| SCB10-1000/10 | 1000 | 1780 | 7150 | 1.0 | 52 | 6 | 820 | 3180 | 1600 × 970 × 1510 |

| SCB10-1250/10 | 1250 | 2100 | 8530 | 1.0 | 52 | 6 | 820 | 3630 | 1720 × 970 × 1615 |

| SCB10-1600/10 | 1600 | 2470 | 10300 | 1.0 | 55 | 6 | 820 | 4280 | 1720 × 1000 × 1825 |

| SCB10-2000/10 | 2000 | 3060 | 12720 | 0.8 | 55 | 6 | 1070 | 5530 | 1850 × 1200 × 1715 |

| SCB10-2500/10 | 2500 | 3600 | 15110 | 0.8 | 57 | 6 | 1070 | 6220 | 1920 × 1200 × 1955 |

| SCB10-1600/10 | 1600 | 2480 | 11390 | 1.0 | 55 | 8 | 1070 | 4410 | 1720 × 1000 × 1825 |

| SCB10-2000/10 | 2000 | 3060 | 14050 | 0.8 | 55 | 8 | 1070 | 5690 | 1850 × 1200 × 1715 |

| SCB10-2500/10 | 2500 | 3600 | 16630 | 0.8 | 57 | 8 | 1070 | 6400 | 1920 × 1200 × 1955 |

| Rate capacity (kVA) | No-load loss (W) | Load loss (W) | Sound level (dB) | Weight (kg) | Dimension (mm) | LV terminal | No-load current (%) | Impedance voltage (%) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | c | d | ||||||||

| 30 | 220 | 660 | 40 | 280 | 600 | 400 | 650 | 350 | 25 × 3 | 2.0 | 4.0 |

| 50 | 310 | 930 | 42 | 340 | 600 | 400 | 705 | 350 | 25 × 3 | 1.5 | |

| 80 | 420 | 1280 | 44 | 565 | 730 | 500 | 740 | 450 | 25 × 3 | 1.1 | |

| 100 | 450 | 1460 | 46 | 610 | 760 | 500 | 775 | 450 | 30 × 3 | 1.1 | |

| 125 | 530 | 1710 | 48 | 640 | 760 | 500 | 840 | 450 | 30 × 3 | 1.0 | |

| 160 | 610 | 1970 | 50 | 830 | 1060 | 600 | 1000 | 550 | 40 × 3 | 0.9 | |

| 200 | 700 | 2340 | 50 | 990 | 1070 | 600 | 1050 | 550 | 40 × 3 | 0.9 | |

| 250 | 810 | 2550 | 50 | 1160 | 1120 | 750 | 1080 | 550 | 40 × 4 | 0.9 | |

| 315 | 990 | 3210 | 51 | 1340 | 1120 | 750 | 1135 | 660 | 50 × 4 | 0.8 | |

| 400 | 1100 | 3690 | 51 | 1600 | 1210 | 750 | 1225 | 660 | 50 × 5 | 0.8 | |

| 500 | 1310 | 4520 | 53 | 1830 | 1260 | 750 | 1185 | 660 | 60 × 5 | 0.7 | |

| 630 | 1460 | 5510 | 53 | 1870 | 1440 | 750 | 1180 | 660 | 60 × 6 | 0.6 | 6.0 |

| 800 | 1710 | 6430 | 53 | 2140 | 1470 | 750 | 1285 | 660 | 80 × 6 | 0.5 | |

| 1000 | 1990 | 7520 | 55 | 2500 | 1520 | 900 | 1325 | 820 | 80 × 8 | 0.5 | |

| 1250 | 2350 | 8960 | 55 | 2980 | 1640 | 900 | 1355 | 820 | 100 × 8 | 0.4 | |

| 1600 | 2760 | 10830 | 55 | 3530 | 1710 | 900 | 1510 | 820 | 100 × 10 | 0.4 | |

| 2000 | 3400 | 13360 | 55 | 4450 | 1820 | 1200 | 1565 | 1070 | 100 × 12 | 0.3 | |

| 2500 | 4000 | 15880 | 55 | 5230 | 1920 | 1200 | 1680 | 1070 | 120 × 12 | 0.3 | |

| 1600 | 2760 | 11970 | 55 | 3630 | 1800 | 900 | 1480 | 820 | 100 × 10 | 0.4 | 8.0 |

| 2000 | 3400 | 14760 | 55 | 4550 | 1900 | 1200 | 1540 | 1070 | 100 × 12 | 0.3 | |

| 2500 | 4000 | 17470 | 55 | 5330 | 2010 | 1200 | 1650 | 1070 | 120 × 12 | 0.3 | |

Dry type transformer are widely used in-

- Fire-risk areas (e.g. forests)

- Environmentally sensitive areas (e.g. water protection areas)

- Chemical, oil and gas industry

- Renewable generation (e.g. off-shore wind turbines)

- Indoor and underground substations

- Inner-city substations

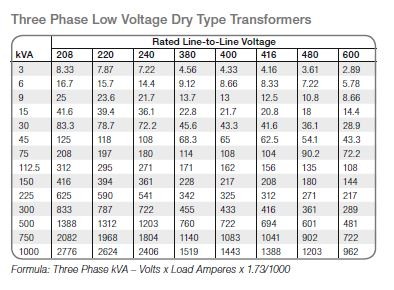

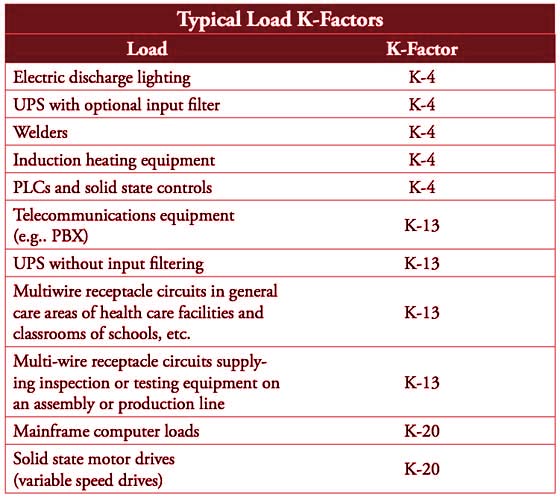

A K-Factor rating is an file of the transformers capacity to supply harmonic substance in its load current whereas working inside it temperature limits. For Dry Type Transformers a K-Factor calculation is made to decide the sum of the Harmonic Substance display in a power framework. K-Rated transformers are measured to handle 100% of the basic 60 Hz load, additionally the non-linear load indicated. The impartial of the K-Rated transformer is measured at 300% of the current rating of the phase associations. Industry writing and commentary refers to a restricted number of K-factor evaluations: K-20, K-4, K-1, K-13, K9, K-40, K-30. A transformer might be planned for other K-factor rating in between those values, as well as for higher values.

The following rules will generally result in an acceptable choice of K-factor value:

- Follow successful practice in sizing the transformer.

- Where the harmonic current producing equipment is less than 15 per cent, use a standard transformer.

- Where the electronic equipment represents up to 35 per cent of the load, use a K-4 rated transformer.

- Where the electronic equipment represents up to 75 per cent of the load, use a K-13 rated transformer.

- Where 100 per cent of the load is electronic equipment, use a K-20 rated transformer.

- Higher K-factor ratings are generally reserved for specific pieces of equipment where the harmonic spectrum of the load is known.

Kindly click here for dry type transformer manufacturing process

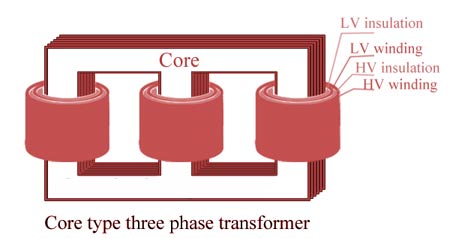

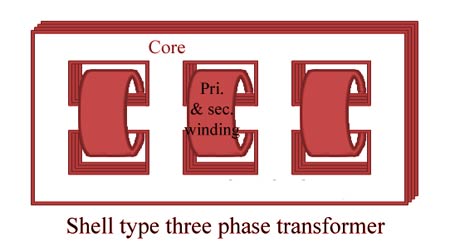

dry type transformer can be of core type or shell type (just like single phase transformers).

Core Type Construction of dry type transformer

The construction of a core type three phase transformer is as appeared within the figure. The core comprises of three legs or limbs. As normal, the core is made up of lean covered sheets to reduce eddy current misfortunes. Each limb has essential and auxiliary windings in round and hollow shape (former wound) organized concentrically.

Shell Type Construction of dry type transformer

In a shell type three phase transformer, three phases are more autonomous than they are in core type. Each phase has its individual magnetic circuit. The construction of shell type three phase transformer is outlined within the figure at below. The construction is comparative to that of three single phase shell type transformers kept on the best of each other.

|

|