low losses transformer manufacturers in india

Prestige Quality low loss power transformers suppliers in africa, view super low loss transformers price

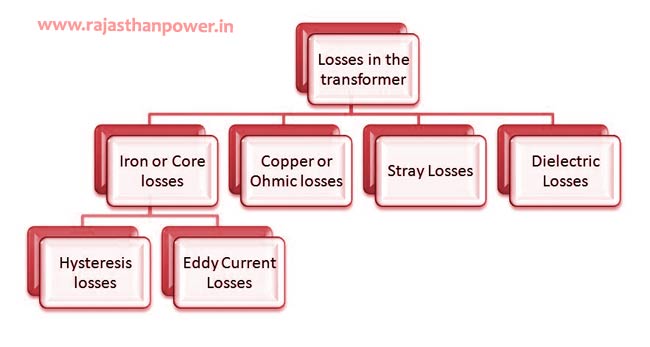

There are various kinds of losses which could occur in the transformer. For instance, the transformer could face losses such as iron losses, hysteresis losses, eddy current losses, copper losses, stray loss, and dielectric losses.

- What is low losses transformer ?

- What are no-load losses?

- low loss transformer specification

- low loss transformers price

- Types of Losses in a Transformer

- Why Energy Losses In Transformer ?

- How To Reduce Transformer Losses At Design Stage

- low loss concept transformer Testing

- low loss transformer application

- low loss transformer Benefits

low losses transformer manufacturers in india

super low loss transformers

low loss concept transformer

World-Class low loss distribution transformers, low loss transformer core Exporter in india, view low loss transformer specification

low loss transformers aid in reducing energy bills, operating cost and they also have an impact on the environment. Generally, a low losses transformer could significantly create financial savings. Which means that this particular type of transformer can be used to not only optimise the end users voltage management, but also act as a part of improving the energy efficiency while being resilient to the buyers site.

Installing a low loss transformer specification could potentially reduce the energy consumption by up to 12% in the end. The transformer produced in our factory proves to be the ideal product, especially for those buyers who tend to be Carbon Conscious. In addition to lowering your CO2 or carbon di-oxide production by around 23 tons per annum low loss concept transformer is also available with a biodegradable Midel fluid.

Using our low loss transformer core also results in a reduced Downtime for Installation. Transformer low load losses have been designed to a similar footprint like those transformers which are already existing in the market. Which in turn, results in lower installation costs, as mentioned by reducing the site downtime as well as minimal changeover disruption.

As one of the leading low losses transformer manufacturers in India, we offer voltage optimisation solutions for Low Loss as well as Super Low Loss transformers. These low loss power transformers meet and exceed the 2021 EU Eco Design specifications.A No-load loss is the loss that takes place in a transformer when it is excited at rated voltage and frequency, but without a load connected which has been the secondary. Examples of no loss loads include – dielectric loss, core loss, and copper loss in the winding due to exciting current.

We are one of the leading super low loss transformers suppliers as well as low losses transformer manufacturers in India.

Electrical energy is transmitted by Electrical transformer and is used to transfer electricity to homes and business from power plants. Low losses transformer manufacturers in India, Rajasthan Powergen use these transformers for transmitting high power over long distances to make it economically viable. Low Loss Transformers can altogether make money related investment funds by upgrading your voltage administration and progressing the vitality proficiency and strength of your site. Installing a low loss transformer can potential diminish vitality utilization by up to 12%.

Load losses basically include the generation of heat from the resistance to current flow through conductor wires. Losses increment with loading on the transformer. Current flows through conductor wires and an iron core.

Core Losses divided in two parts.

- hysteresis loss

This loss is due to magnetic properties of iron part or core.

- Eddy current loss.

Eddy current loss takes place when a coil is wrapped around a core and substituting ac supply is connected to it.

Transformers moreover show no-load (core) losses, which result from magnetizing current within the core. Most core losses are either hysteresis or eddy current losses. Hysteresis losses come from core lamination’s resistance to always being magnetized and demagnetized. Eddy current losses result from circular electric currents. When there’s no load on the secondary side and the essential side is still energized, the iron core still encounters these losses

Super Low Loss transformers combine mechanically advanced core materials with low loss conductors. Energy bills and operating costs can be decreased and it can also lighten the environmental impact. High voltage sites can advantage by reducing their power consumption through upgrading their required output voltage.

In addition, super low loss transformers are:

- interchangeable with most transformer installations

- built to IEC60076/BSEN60076 standard

- designed to tap up or tap down to optimise voltage requirements for individual sites.

- require no additional voltage optimisation to be installed as a second stage

| Phase | Three Phase |

| Frequency | 50 Hz |

| Winding Material | Copper/Aluminium |

| Ratings | Upto 200 kVA |

| Primary voltage | Upto 11000 V |

| Secondary Voltage | 433 V |

| Temperature Rise | 35 C / 40 C |

| low losses transformer manufacturers in india export to | Tanzania, India, Africa, Rwanda, Kenya, Nigeria, Bangladesh, Malaysia Malawi, Nepal, Uganda |

Request A Quote Today For transformer low load losses, low loss type transformers, super low loss transformers price

For Final low losses transformer price india Please Mail Us on info@rajasthanpower.in

There are various types of losses in the transformer such as copper losses, iron losses, eddy current losses, hysteresis losses,dielectric losses and stray loss. The various types of losses are explained below in detail.

- Iron Losses

- Hysteresis Loss

- Eddy Current Loss

- Copper Loss Or Ohmic Loss

- Stray Loss

- Dielectric Loss

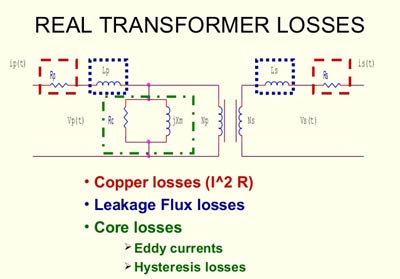

Although transformers are exceptionally proficient devices, small energy losses do happen in them due to four primary causes:

- Resistance of windings

- Flux leakage

- Eddy currents

- Hysteresis

| Distribution Transformer in KVA | Level 1 rated Transformer | Level 2 rated Transformer | ||

| *Total loss in watts at 100 % loading should not be lower than (Not equal to) |

*Total loss in watts at 100 % loading should not be higher than |

*Total loss in watts at 100 % loading should not be lower than (Not equal to) | *Total loss in watts at 100 % loading should not be higher than |

|

|

5 |

95 |

115 |

75 |

95 |

|

10 |

240 |

270 |

215 |

240 |

|

16 |

440 |

480 |

400 |

440 |

|

25 |

635 |

695 |

595 |

635 |

|

63 |

1140 |

1250 |

1050 |

1140 |

|

100 |

1650 |

1800 |

1500 |

1650 |

|

200 |

2300 |

2700 |

2100 |

2300 |

|

500 |

4300 |

4750 |

4100 |

4300 |

An increment in volts per turn reduces winding loss whereas expanding the core loss.To raise transformer effectiveness, core loss has likely drawn the foremost consideration. Core development grants two critical energy-saving highlights not applicable to industrial engines. To begin with, the inherent colinearity between lamination orientation and the magnetic field direction permits utilize of grain situated steel for transformer laminations.

Second, since laminations are sheared or opening in strips instead of being punched with slots, much thinner material can be utilized in a transformer core than in a turning machine. Though engine laminations are usually 0.014 to 0.025 inch thick, transformer cover thickness may be as low as 0.006, with 0.009 to 0.012 being common. That lowers eddy current loss.

Below are the tests conducted before delivery. Other tests required by clients can also be done accordingly.

- Insulation resistance

- Resistance of all windings

- Check voltage ratio and vector group

- No-load test at rated frequency and rated voltage

- Impedance test

- Withstand voltage testing

- Induced over-voltage withstand testing

- Partial discharge measurement

- Oil leakage test

- Wind Farm Transformers

- Isolation Transformers

- Voltage Management

- Data Centres

- Step Down Distribution Transformers

- Step Up Generation Transformers

- Unit Type Substations

- Solar PV Farm Transformers

- Package Substations

- Up to £100k lifetime savings when replacing an existing transformer

- Meets and exceeds 2021 Eu Eco Design specifications

- Cost effective Voltage Management solution (3% – 12% of electricity savings)

- Guaranteed loss savings over lifetime

- Warranty and guarantee

- Easy non-invasive energy efficiency measure

- Traditional ‘standard’ loss transformers are efficient devices, however low loss transformers are more efficient – saving money from reduced losses and increased energy efficiency

- By using low loss transformers it is possible to achieve huge energy cost savings in a relatively short period of time

- In addition, low loss transformers can be supplied with directly mounted MV & LV switchgear to form an assembled package substation