electric arc furnace transformer manufacturers in india

A Full Range Of dc electric arc furnace transformers, induction furnace transformer suppliers in africa, view 24v furnace transformer price

Furnace control transformer is a transformer used in a furnace. Furnace ignition transformer is used in applications where an electric arc is used to melt the contents of the furnace. The tapchangers for arc furnace transformer need much attention. The number of operations and the tap changing duty are very high compared to a system transformer. Rajasthan Powergen Transformer P. Ltd. is one of the electric arc furnace transformer manufacturers in India.

electric arc furnace transformer manufacturers in india

induction furnace transformer

24v furnace transformer

Carries A Complete Line Of furnace 24 volt transformer, gas furnace transformer, furnace ignition transformer Exporter in india, view electric furnace transformer price

Furnace Ignition Transformer types

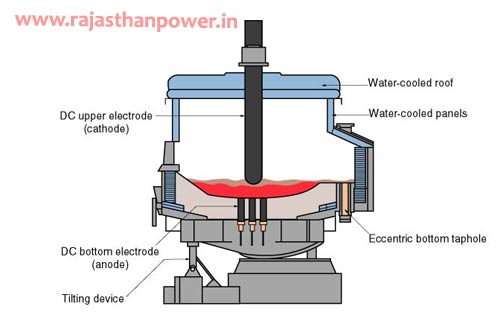

The main partition is by current; either DC or AC. As the names indicate, an AC transformer works on alternating current whereas the DC electric arc furnace transformer works in DC current. A 24v furnace transformer operates under 24 volts of electric voltage difference. A furnace 24 volt transformer might sometimes be mistaken for a doorbell transformer. But they are very different things and there is no such thing as a furnace doorbell transformer.

Induction furnace transformer uses the available 3 phase AC electricity to provide the necessary DC electricity to the induction system. The induction system produces eddy currents in the charge and heats the contents of the furnace. A gas furnace transformer is used in a gas furnace. Furnace oil transformer is used to heating up the oil in an oil furnace before ignition. Transformer for electric furnace can be applied for 120v to 24v transformer furnace. A furnace thermostat transformer works with a thermostat in a transformer to automatically switch on or off the furnace. A 24 volt furnace transformer is very energy efficient as it requires such low loads of voltage.

Electric arc furnace transformer

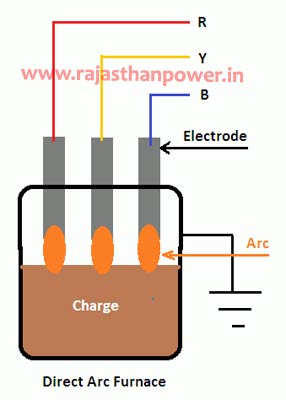

There is a solid difference between an induction furnace and an electric arc furnace. The induction furnace uses an induction system where the materials to heat up are put inside a container where they are heated by eddy currents resulting from the induction system. For this, DC currents are used, and the specified transformers are used. The electric arc furnace on the other hand uses charged materials to be heated. The electricity flows right through the materials in the form of an electric arc which requires very high voltage and load of currents. The electric arc passes through the material and heats it up much faster than the induction system.

Electric Furnace Transformer Price have their differences due to the labor cost incurred in the manufacturing countries. As for the electric arc furnace transformer manufacturers in India, the labor costs are cut down by about 30% and the prices are low compared to foreign productions. And Rajasthan Powergen Transformer P. Ltd. is one of the well-known electric arc furnace transformer manufacturers in India.

An electric arc furnace (EAF) could be a furnace that warms charged material by means of an electric arc. A furnace transformer is utilized to supply power to an electric furnace, which brings down the high voltage to the lower voltage required for Arc Furnace applications. Furnace Transformers from Rajasthan Powergen Transformer P. Ltd support high voltages up to 138 kV, 650 kV BIL and ratings up to 50 MVA (ONAN).

we produces transformers for all furnace applications, counting long-arc (steel) and short-arc (ferro-alloy) operation.A robust design ensures mechanical quality for steel furnace operation and temperature control for nonstop high loads in ferro-alloy operation.Arc heaters vary from acceptance heaters in that the charge fabric is specifically uncovered to an electric arc and the current within the furnace terminals passes through the charged material.

| electric arc furnace transformer Rating | Up to 30MVA |

| Primary Voltage | Up to 33kV |

| Secondary Voltage | As per requirement |

| electric arc furnace transformer No of Phase | Single & Three Phase |

| Cooling | ONAN/OFWF |

| Winding Material | Copper |

| electric arc furnace transformer Tapping | Off circuit or OLTC |

| Insulation Class | A |

| electric arc furnace transformer manufacturers Manufacturers Export to | Nigeria, Tanzania, Africa, Uganda, Kenya, Rwanda, India, Malaysia Bangladesh, Malawi, Nepal, |

| Applicable Standards | IS2026, IS12977 |

|

Technical Details

|

|||

|

Power (KW)

|

Open-circuitVoltage (V)

|

Pipe Flow (A)

|

Overall Dimension (mm)

|

|

3

|

700

|

5

|

330x230x230

|

|

4

|

670

|

6.5

|

330x240x240

|

|

5

|

850

|

6.5

|

380x70x240

|

|

5.6

|

950

|

7

|

380x280x240

|

|

6

|

850

|

7.5

|

380x290x240

|

|

6.5

|

900

|

7.5

|

400x290x250

|

|

7.2

|

1100

|

7

|

400x290x250

|

|

8-A

|

1200

|

7.5

|

400x300x250

|

|

8-B

|

1650

|

5.5

|

400x300x250

|

|

8-C

|

950

|

8.8

|

400x300x250

|

|

8.4

|

950

|

9

|

410x300x250

|

|

9-A

|

1500

|

7.6

|

410x310x260

|

|

9-New

|

2000

|

4.6

|

410x310x260

|

|

9.6

|

1570

|

6.6

|

420x310x270

|

|

10

|

2000

|

5.5

|

420x310x270

|

|

10-New

|

2000

|

5.5

|

440x310x270

|

|

11

|

1870

|

6.4

|

440x330x300

|

|

12

|

1800

|

7.2

|

440x340x300

|

|

13

|

1870

|

7.5

|

440x345x300

|

|

14

|

1980

|

7.5

|

450x350x330

|

|

15

|

2200

|

7

|

400x350x330

|

|

16

|

2500

|

7

|

460x350x300

|

For Final electric arc furnace transformer price india Please Mail Us on info@rajasthanpower.in

furnace control transformer

120v to 24v transformer furnace

furnace thermostat transformer

24 volt transformer

India’s Largest Manufacturer Of furnace ignition transformer, furnace doorbell transformer, furnace oil transformer, arc furnace transformer at low cost in india

There are two types of arc furnaces namely:

- Direct Electric Arc Furnace

- Indirect Electric Arc Furnace

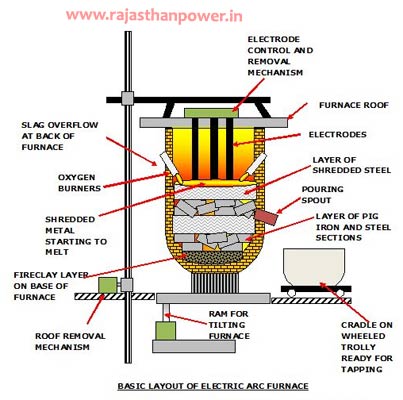

The working of electric furnace incorporates charging the electrode, emergency period (melting the metal) and refining. The overwhelming and light scrap within the large basket is preheated with the assistance of exhaust gas. For speeding up the slag arrangement, burnt lime and fight are included to it. The charging of furnace takes put by swinging the roof of the heater. As per prerequisite, the hot metal charging moreover takes place.

Following is the emergency period. The electrodes are moved down onto the scrap in this period. At that point the bend is delivered between the electrode and metal. By considering the protection viewpoint, low voltage is chosen for this. After the bend is protected by electrodes, the voltage is expanded for speeding up the melting process. In this process, carbon, silicon, and manganese get oxidized. The lower current is required for expansive arc generation. The heat loss is additionally less in this. Melting down prepare can be securing by deep washing of electrodes.

Refining process begins during melting. The removal of sulfur isn’t fundamental for single oxidizing slag practice. As it were phosphorous removal is required in this. But in double slag practice, both (S and P) are to be evacuated. After the deoxidizing; in double slag practice, the evacuation of oxidizing slag is performed. Next, with the assistance of aluminum or ferromanganese or ferrosilicon, it gets deoxidized. When the showering chemistry and required temperature is come to, the warm will get deoxidized. At that point, the liquid metal is prepared for tapping.

The most parts of electric furnace are the roof, terminals, hearth (lower portion of a heater, from where liquid metal is collected) and side walls. The roof comprises of three holes through which the electrodes are embedded. The roof is made up of alumina and magnesite-chromite bricks. The hearth incorporates metal and slag. The tilting component is utilized to pour the metal that’s liquid to the support by moving the furnace.

For the electrode expulsion and furnace charging (topping up scrap metals), roof withdrawal component is incorporated. The arrangement for smolder extraction is additionally given around the heater considering the wellbeing of administrators. In AC electric furnace, anodes are three in number. These are round in segment. Graphite is utilized as electrodes since of high electric conductivity. Carbon electrodes are too utilized. The terminals situating framework helps to raise and lower the anodes consequently. The electrodes get profoundly oxidized when the current thickness is high.

- Provided with OFWF cooling with 100% ,standby capacity

- Direct or indirect regulation

- Can be provided with Off circuit tap changer and On load tap changer

- Very High currents as compared to Conventional transformers

- Withstand harmonics generated due to rectifier, furnace operation

- Provides large low voltage variation to suit furnace application

Transformer failures are unusual to hear about. In case of too high a voltage or current passing through the coil, the circuit breaks down by the heating of the winding.

The breakdown of the primary and secondary winding can also be checked and it is easier in case of a linear transformer. It can be done by applying ac voltage to the primary winding. If there is very low or absence of voltage from the secondary side then it signifies the opening of the winding of the transformer. Signs of overheating like the peculiar smell can be easily noticed. Testing a power transformer is a little tough as load has to be connected without which there are chances of overload. Linear transformer are the ones which can be tested in the absence of load and the switch mode power supply work with load while linear transformer can be test without load.

So to test a switch mode power transformer firstly one has to disconnect it from the board and then Check the primary winding because it is very for secondary winding to fail. One can distinguish primary winding from the secondary by Using a filter cap. The positive pin of the bag will go to the pin of the transformer and the middle pin that is the drain will lead to a pin of the transformer . These two pins make primary winding. This method through resistance checks if the coil ha opened or not. So to check if it has shortened or not one has to apply ringer test.

The most cost effective ringer tester is Dick Smith LOPT METER or flyback tester. It can instantly tell the results on the bar graph by connecting its probes to the primary winding. A reading of 4-8 means full winding, 1-2 bar signifies partial shortening and switching off of the represents heavy shortening in the coil.

The equipment is an expensive ringer which can check all kinds of windings of all the transformers. Transformer repair requires skill and knowledge and is definitely not easy to perform. The people who repair the transformers like to rewind the bigger windings like the fan, car alternator etc . This make the Switch mode power transformer a bit tough to rewind owning to its small size and cheap pricing.

- Decrease in electrode consumption by 50%.

- Melting is almost uniform.

- Decrease in power consumption (5 to 10%).

- Decrease in flicker by 50%.

- Decrease in refractory consumption

- Hearth life can be extended.

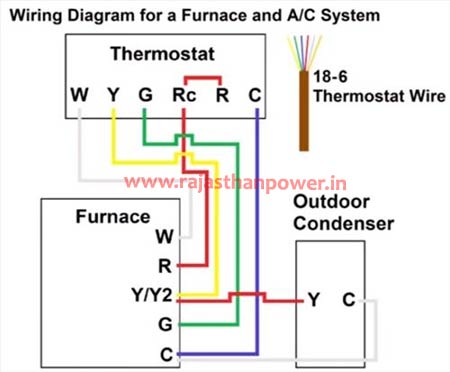

When an HVAC (Heating, Ventilation, Air Conditioning) framework doesn’t work quite because it should, exceptionally frequently it can be followed to a issue with the thermostat. Since these are simpler to fix, the thermostat is the primary place to seek for issues. In the event that the inconvenience isn’t there, at that point the issue may be within the furnace itself.

There are three HVAC side effects that can frequently be followed to issues with the thermostat:

- The furnace does not set the temperature to the desired level—it is either too cold or too warm

- The system produces no heat or cooled air

- The system cycles (turns on and off) too frequently

Possible Causes

- Loose wires or open connection in the thermostat

- Thermostat components are dirty

- A bad battery on digital electronic thermostats

- Circuit breaker tripped or fuse is blown

Possible electric furnace transformer troubleshooting:

- Reset circuit breaker or replace burned out fuse

- Remove thermostat cover and gently clean components, especially the bimetallic coil and the switch contact surfaces.

- Set the thermostat to its lowest setting and clean the bimetallic coil with a soft brush or compressed air.

- Set the thermostat to its highest setting and clean the coil again.

- Then, reset the thermostat to its desired setting.

- Tighten any loose screw terminals.

- If a wire is loose from its terminal, place the wire back on the terminal clamp and tighten the screw.

- Check for loose connections or disconnected wires on a low-voltage transformer, which is usually mounted on the furnace.

- On electronic thermostat models, check to see if the display is working, indicating power. If it is not working, replace the batteries in the thermostat.

- Loose wire

- Clogged filter

- Contact with water

- Wrong fuse

- Dirty fuse

- Faulty starting capacitor

- Transformer failure

- Bad blower motor

- Failing valve

- Electric furnace thermostat control wire

You’ll avoid nearly all of these issues by routinely keeping up your HVAC system.If you’ve been ignoring HVAC preventative upkeep, you will be shocked to discover that it’s not as costly as you thought, and can really pay for itself in cost savings. Preventative upkeep contracts can be designed to suit wants of your equipment, your business and your budget.

- Non Ferrous Metal industries

- Rolling mills

- Industries (Cement, Steel, Mining etc.,)

- Steel plant

|

|